A team in the chemistry department at Fordham University has been working for the past two years to create an air filtration system that would cleanse the air of contaminants without releasing harmful byproducts, as the current photocatalytic oxidation (PCO) systems can do.

The team consists of four undergraduate students headed by Professor Chris Koenigsmann, associate professor and chair of the chemistry and biochemistry department, and Dr. Lukasz Sztaberek, an assistant professor in the Environmental Control Department at the New York College of Technology. The research project was a joint idea by Koenigismann and Sztaberek to look into the conditions that cause PCO systems to create harmful byproducts and to figure out how to create a technology that would not produce those byproducts.

“[Sztaberek’s] professorship at the other institution is in HVAC engineering, which is like heating, cooling, air conditioning, things like that, and obviously, I’m a chemist,” Koenigsmann said. “We had this sort of joint idea that we could take my expertise in catalysis and his expertise in HVAC engineering and merge those to solve a problem.”

Current PCO air purifiers use a catalyst and ultraviolet light to oxidize the air and cleanse it of contaminants, including COVID-19. However, these systems can affect air quality in other ways, releasing toxic chemicals, such as formaldehyde, into the air. In response to this issue, Koenigsmann’s team has been conducting experiments to test what conditions and catalysts can be used to prevent these byproducts from being created.

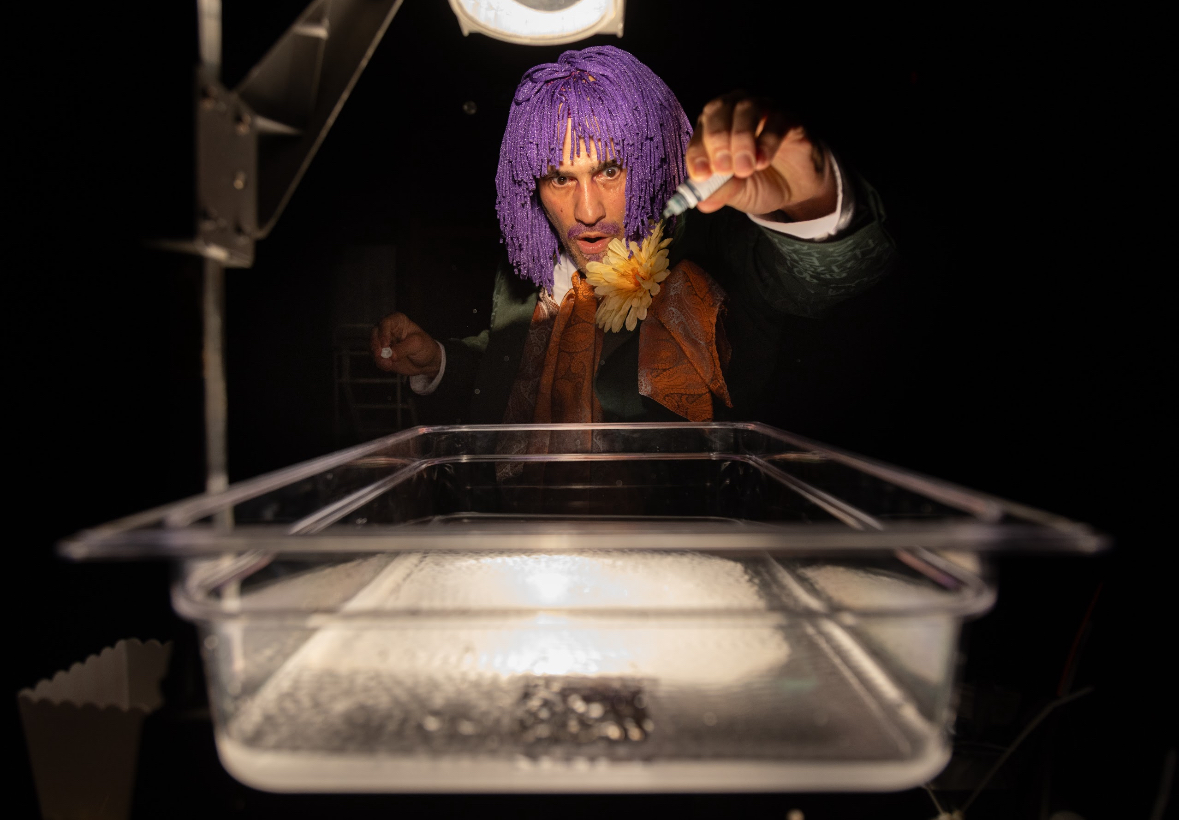

The experiments involve synthesis, catalysis and filtration, all conducted by the students on the team. In their research, they have found some catalysts to be effective and others to be ineffective. Two of the catalysts they tested were zirconium and vanadium, which have similar properties on the periodic table. Zirconium proved effective as it successfully increased the band gap, a property of the catalyst that aids in its efficiency in breaking down contaminants in the air. The zirconium also showed a consistent trend in the data sets they collected. However, they did not find the same success with vanadium yet.

“Whatever we did, it just didn’t work. But the main prong of the project is zirconium. Vanadium, it would be cool if we could figure that out,” said Jack Loughney, FCRH ’26.

Koenigsmann believes research and involvement in research projects are critical, especially for STEM students, as they provide hands-on experience. Additionally, he feels that experiencing roadblocks and struggles during experimentation, such as the struggles they have faced with vanadium, are intrinsic to the students.

“In science, facing down that challenge in an environment where you have someone to guide you through it is the most valuable thing about research,” Koenigsmann said. The student researchers agree that these projects are valuable experiences for students to have. According to Loughney, Arham Jamshaid, FCRH ’26, and David Chacon, FCRH ’25, they provide the ability to fail without grades on the line, as well as teaching essential skills and risk-taking.

“In my opinion, even if your interest, say, is in heart surgery, I think doing research in something completely separate to that is still valuable because it really is just about training the researcher mind, the inquisitive mind,” Chacon said.

The current project is being funded by the Halton Foundation, a “charitable organization with the aim of improving indoor environmental quality,” which granted Koenigsmann’s team a three-year, $90,000 grant in 2023. Fordham has also provided some funding for the project as they award grants to students conducting research projects. Koenigsmann anticipates the current project’s time horizon of one to two years. However, he says that once they answer their current research question, they will likely pose a new one and begin new experiments.

While the project’s goal is not to make a commercial product, the team hopes to be soon able to publish a research paper so that other scientists may use the information to create commercial products themselves.

“We want to understand how changing certain parameters about the catalyst changes how the catalyst works; then those design principles, which we publish, can inform the community on how to then build a more commercially robust catalyst,” Koenigsmann said. “It is theoretically possible that we might develop a catalyst that is commercially viable, in which case we would seek to patent that; but that is not necessarily our goal.”